Please click on the + icon below to expand the FAQs for our product lines.

Don’t see a question that you would like answered? We’re the floor solutions experts – ask away!

Flex Scrub® FAQ Section:

Q: Can you purchase the Flex Coupler™ separately?

A: No, the Flex Coupler™ does not detach from the Flex Scrub®. If you’re in need of a replacement Flex Coupler™, you will need to replace the entire bristled pad.

Q: What type of machine can I use Flex Scrub® on?

A: Flex Scrub® bristled floor pads work with most standard floor machines: 175-350 RPM’s (single disc machines, auto-scrubbers, ride-on and orbital). Quickly attaches to any pad driver.

Q: Can you use a Flex Scrub® on all orbital floor machines?

A: Flex Scrub® will work on all pad drivers made with a standard recessed center hole area. This allows room for the Flex Coupler™.

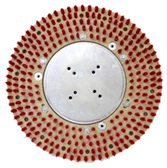

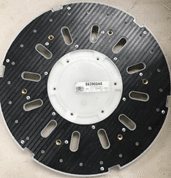

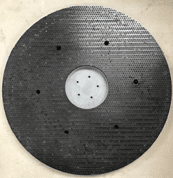

Exclusions include machines designed with a flat disc pad driver; examples pictured below.

Q: What color Flex Scrub® should I purchase?

A: Purchase the same color Flex Scrub® as the floor pad you are currently using.

Q: What size Flex Scrub® should I order?

A: Order the same size Flex Scrub® as your pad driver.

Q: What sizes does Flex Scrub® come in?

A: Flex Scrub® Bristled Floor pads come in five sizes: 13”, 16”, 17”, 19”, and 20”.

Q: How do I know when I need to replace my Flex Scrub®?

A: Replace Flex Scrub® when bristles have about ½” length remaining.

Q: If I currently buy and use grit brushes, should I buy Flex Scrub® instead?

A: No, continue to use grit brushes. Flex Scrub® is not a replacement for a grit brush; it is a replacement for a pad.

Q: How long will a Flex Scrub® Bristled Floor pad last?

A: Our testing shows that if you use the same color Flex Scrub® as a floor pad, the Flex Scrub will last up to 50 times longer than one traditional floor pad.

Q: Will the Polypropylene scratch the floor?

A: The Polypropylene in the Flex Scrub® will not scratch the floor if you are using the proper Flex Scrub® for the floor type. Reference our application guide for details.

Q: Is the Black Flex Scrub® effective in taking off floor wax like a traditional pad can?

A: When used with a chemical stripper, the Black Flex Scrub® removes the floor wax more quickly, which increases worker productivity. Black Flex Scrubs® do not gum up when stripping. Black floor pads gum up after 150 sq ft, they need to be flipped and washed out while Black Flex Scrubs® are self-cleaning.

Q: Can the Flex Scrub® polish floors?

A: Flex Scrub is not intended to polish, but to clean and strip, depending on the color Flex Scrub® you use.

Q: Are there enough tufts in a Flex Scrub® to clean the floor well?

A: There are more than enough tufts on a Flex Scrub to properly loosen the dirt and agitate chemicals/water on the floor to achieve a clean result. The bristles agitate and remove the dirt in both the highs and lows of the floors and in grout lines, where traditional pads only smear the dirt and spread it across the surface of the floor.

Q: Can you use Flex Scrub® on LVT?

A: No, we suggest using our Soft White Nylon brush on LVT.

Diamond Devil®; Polishing System FAQ Section:

Q: Which tool do I start with when restoring and polishing concrete floors?

A: It is important to know what condition your concrete is in before starting.

- How old is the concrete?

- Has it been polished before?

- On a scale from one to six, what condition is your concrete?

- 1 – Pitted

- 2 – Rough (Grind Tool – Blue)

- 3 –Semi-smooth (Grind Tool -Blue)

- 4- Smooth with matte finish (Hone Tool -Green)

- 5 – Smooth with some reflection (Polish Tool – Natural)

- 6 – Smooth with reflection (+1 Shine Tool – Red)

- It is recommended that 6 passes are done with each tool in the system: Grind, Hone and Polish.

- Add in the +1 Shine (Red) Tool if you want to elevate the gloss level beyond industry standards:

- Starting with the Grind (Blue) Tool used to remove light coatings and preps floor with an open finish

- Hone (Green) Tool used to set concrete to a honed finish, ready for polish

- Polish (Natural) Tool closes concrete and brings out a clean satin/polished finish

- +1 Shine (Red) Tool used to enhance and maintain your polished floors to an unmatched gloss level using only your standard floor machine

Not sure where to start? Contact a Diamond Devil® specialist today.

Q: What grit diamonds are in each tool?

A: The Diamond Devil®; Concrete Restoration and Polishing tools are not assigned a specific grit level,

as they are formulated with a proprietary diamond abrasive blend that is unique to our system.

Q: What is the expected life of each of the tools?

A: The life expectancy of each tool will vary depending on the condition of the concrete.

Contact one of our Diamond Devil®; Specialists to get a square footage estimate.

Q: Will the colored blades stain or bleed onto my floor?

A: No. the colorant in the blades will not transfer into the floor.

If you are seeing color in the slurry, that is indicative of selecting the wrong tool for the profile of the

surface. You may want to drop back to the next lowest polishing step before continuing.

If you have questions, please contact one of our Diamond Devil® Specialists for assistance.

Q: Which tool do I use to maintain my polished concrete or terrazzo floor?

A: For outstanding results use our natural color Polish tool. If you are looking for an unmatched reflective

shine, we suggest using our red-colored Shine Tool. Watch this video for more info.

Q: How do I know when my concrete polishing tool is worn out and it’s time to be replaced?

A: When using the maintenance tool, check wear weekly.

Check for the black wear indicator coming through on the Blade as shown in examples below:

Q: What size tool do I purchase based on the size of my machine?

A: Auto Scrubbers will require the same size Diamond Devil®; Tool as the pad driver size recommended for the machine.

For Standard Single Disc or low-speed electric floor machines, Diamond Devil®; tools can be sized up one size from the recommended pad driver size and ordered with a 1 1/2” riser to accommodate edging.

Q: Are the tools directional?

A: Yes. Typically, low-speed electric floor machines use counter-clockwise (CCW) brushes/tools. However there are few types of single disc floor machines that are clockwise (CW), so it is suggested to confirm the rotation of the machine before mounting tool.

When determining direction, do so from the operator’s viewpoint and not from under the machine. (Click here for rotational instruction video).

For dual headed auto scrubbers, typically the one side spins counter-clockwise (CCW), and the other side spins clockwise (CW) Click here for rotational instructions video.

- NOTE: Tools are rotation sensitive, and it is imperative that the tools are mounted correctly to avoid possible tool or floor machine damage.

Q: How do I assure that my operator doesn’t put the directional blocks on my machine incorrectly?

A: To ensure tools are mounted correctly onto the machine, we strongly suggest that the operator view the

Rotational Instruction Video prior to mounting tools. Once the rotation is determined, the operator should reference the label printed on top of the tool that specifies if the tool is Clockwise (CW) or Counter-Clockwise (CCW).

Q: What sizes are they available in?

A: Diamond Devil®; Tools are available in sizes 12″ through 20″ block diameters and fit most standard floor machines.

Q: Will blade wear vary from floor to floor?

A: Yes. Blade wear can be affected by the condition of the floor.

Q: Should I use Densifier?

A: Densifier can be used, but is not necessary when using the chemical-free Diamond Devil®; Concrete

Restoration and Polishing System.

Q: Can I use cleaners during the polishing process?

A: Yes, a neutral cleaner can be used, but we recommend using only water with the chemical free Diamond Devil®; Polishing System.

Q: How can I reach the edges of my concrete or terrazzo floors?

A: Edges can only be done using a low-speed electric floor machine (buffer type) because you can oversize tools to extend outside the machine deck, where you cannot with an auto scrubber.

Oversizing tools for floor machines require a riser. For example: Use a 17″ tool with a 1 ½” riser and clutch plate for a 17″ deck floor machine; A 20″ tool with a 1 ½” riser and clutch plate for a 20″ floor machine.

Q: How to polish a concrete floor?

A: It is important to know what condition your concrete is in before starting.

- How old is the concrete?

- Has it been polished before?

- On a scale from one to six, what condition is your concrete?

- 1 – Pitted

- 2 – Rough (Grind Tool – Blue)

- 3 –Semi-smooth (Grind Tool -Blue)

- 4- Smooth with matte finish (Hone Tool -Green)

- 5 – Smooth with some reflection (Polish Tool – Natural)

- 6 – Smooth with reflection (+1 Shine Tool – Red)

* It is recommended that 6 passes are done with each tool in the system: Grind, Hone, and Polish.

Add in the +1 Shine Tool if you want to elevate the gloss level beyond industry standards:

- Starting with the Grind (Blue) Tool used to remove light coatings and preps floor with an open finish

- Hone (Green) Tool used to set concrete to a honed finish, ready for polish

- Polish (Natural) Tool closes concrete and brings out a clean satin/polished finish

- +1 Shine (Red) Tool used to enhance and maintain your polished floors to an unmatched gloss level using only your stand floor machine.

Note:

The Diamond Devil®; Polishing system is not recommended for use on decorative, stained, or brushed concrete. Polishing tools should be used only on indoor troweled concrete.

Before starting any polishing project, we strongly suggest working with one of our Diamond Devil®; specialists. Contact a specialist today

Q: How can I make my concrete floor shine?

A: The Diamond Devil®; Concrete Restoration and Polishing System uses a progression of tools Grind, Hone and Polish that takes concrete floors to an even satin/polished finish. The optional +1 Shine Tool takes the finish a step beyond, to an unmatched superior image gloss and clarity.

Note: All Diamond Devil Tools are used on a standard floor machine or auto-scrubbers

Q: How long does it take to restore (grind) and polish concrete floors?

A: The time required to restore and polish concrete floors varies depending upon the condition of the concrete floor, along with the square footage. The Diamond Devil®; Concrete Restoration and Polishing System is 3 steps -vs- the typical 6-step polishing processing. Less steps, less time on the floor saves time and money. Before starting any polishing project, we strongly suggest working with one our Diamond Devil®; specialists. Contact a specialist today

Q: What tools do you need to polish concrete?

A: It is important to know what condition your concrete is in before starting.

- How old is the concrete?

- Has it been polished before?

- On a scale from one to six, what condition is your concrete?

- 1 – Pitted

- 2 – Rough (Grind Tool – Blue)

- 3 –Semi-smooth (Grind Tool -Blue)

- 4- Smooth with matte finish (Hone Tool -Green)

- 5 – Smooth with some reflection (Polish Tool – Natural)

- 6 – Smooth with reflection (+1 Shine Tool – Red)

- It is recommended that 6 passes are done with each tool in the system: Grind, Hone and Polish.

- Add in the +1 Shine Tool if you want to elevate the gloss level beyond industry standards:

- Starting with the Grind (Blue) Tool used to remove light coatings and preps floor with an open finish

- Hone (Green) Tool used to set concrete to a honed finish, ready for polish

- Polish (Natural) Tool closes concrete and brings out a clean satin/polished finish

- +1 Shine (Red) Tool used to enhance and maintain your polished floors to an unmatched gloss level using only your stand floor machine

Mastic Demon® FAQ Section:

Q: What floor coatings can Diamond Devil® remove?

A: The Diamond Devil® Mastic Demon® Tool easily removes mastic, glue, adhesive, thin-set, paint, thin-mil epoxy, along with other types of coatings from concrete floors.

Q: How to remove mastic and glue from concrete?

A: Using a standard single disc floor machine, attach the Mastic Demon® Tool

- Always run with plenty of water (never run tool dry)

- Start on the edge where you can begin to breakup and work your way across the concrete floor from side- to-side moving slowly. Continue to make passes until desired results are achieved.

- After running the Mastic Demon®; the floor is left with an improved concrete surface profile (CSP) between 2 and 3.

Note: The Mastic Demon® Tool is a standalone tool and is designed to remove coatings and mastic on concrete floors that are not intended for polishing.

It is not to be used as part of the Diamond Devil® Polishing System.

Q: How do you remove old concrete coatings?

A: Using your standard single disc floor machine, attach the Mastic Demon® tool

- Always run with plenty of water (never run tool dry)

- Start on the edge where you can begin to breakup the coating and work your way across the concrete surface moving slowly from side- to-side.

- Continue to make passes until desired results are achieved.

After running the Mastic Demon® the floor is left with an improved surface profile.

Note: The Mastic Demon® is a standalone tool and is designed to remove coatings and mastic on concrete floors that are not intended for polishing. It is not to be used as part of the Diamond Devil® Polishing System. The Mastic Demon® Tool easily removes mastic, glue, adhesive, thin-set, paint, thin-mil epoxy, etc. from concrete floors. This tool cuts into coatings aggressively, leaving an improved surface profile. It works on most standard floor machines and without chemicals.

Q: Why is it important to remove mastic?

A: The old mastic must be removed before applying any new coating to the concrete surface. If the old mastic is not removed, then the new coating will not adhere properly to the concrete.

Q: How to remove mastic adhesive from concrete floors?

A: Using your standard single disc floor machine, attach the Mastic Demon® tool

- Always run with plenty of water (never run tool dry)

- Start on the edge where you can begin to breakup and work your way across the concrete floor from side- to-side moving slowly

- Continue to make passes until desired results are achieved

After running the Mastic Demon® the floor is left with an improved concrete surface profile (CSP) between 2 and 3.

Note: The Mastic Demon® is a standalone tool and is designed to remove coatings and mastic on concrete floors that are not intended for polishing. It is not to be used as part of the Diamond Devil® Polishing System.

Q: What sizes are your concrete mastic removal tools available in?

A: Mastic Demon® Tools are available in sizes 12″ through 20″ block diameters and fit most standard floor machines.

Q: How do I assure that my operator doesn’t put the directional blocks on my machine incorrectly?

A: To ensure tools are mounted correctly onto the machine, we strongly suggest that the operator view the

Rotational Instruction Video prior to mounting tools. Once rotation is determined, the operator should reference the label printed on-top of the tool that specifies if the tool is Clockwise (CW) or Counter-Clockwise (CCW).

Q: Is it easy to get replacement blades?

A: Yes, there are replacement blade kits available for the Mastic Demon® Tools available from your supplier.

Q: What kind of profile does it leave?

A: The Mastic Demon® Tool leaves an improved surface profile that is a CSP between a 2 & 3.

Q: Do I need to use chemicals with the Mastic Demon® tool?

A: No. The Mastic Demon® Tool is chemical-free and is recommended for use with water only.

- NOTE: The Mastic Demon® Tool must be run with water. We do NOT recommend running the tool dry.

Q: Can I use stripping chemicals or degreasers with the Mastic Demon® Tool to speed up the process?

A: No. The Mastic Demon® Tool is chemical free and was designed to deliver excellent results using only water.